HuJin, Manufacturing for Hose Series & Couplings

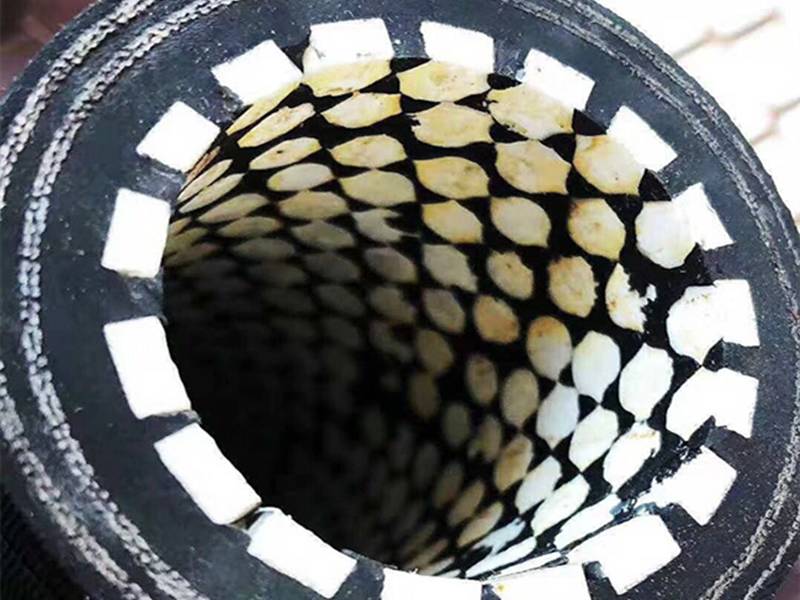

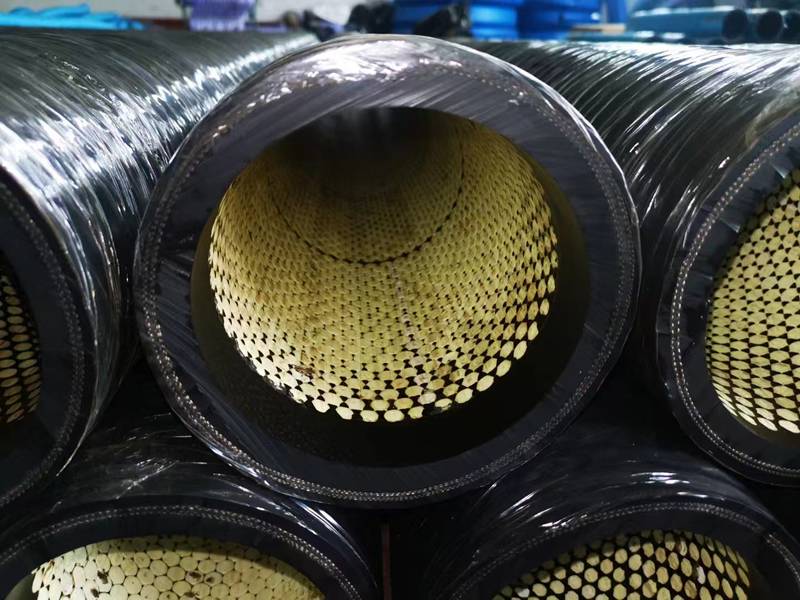

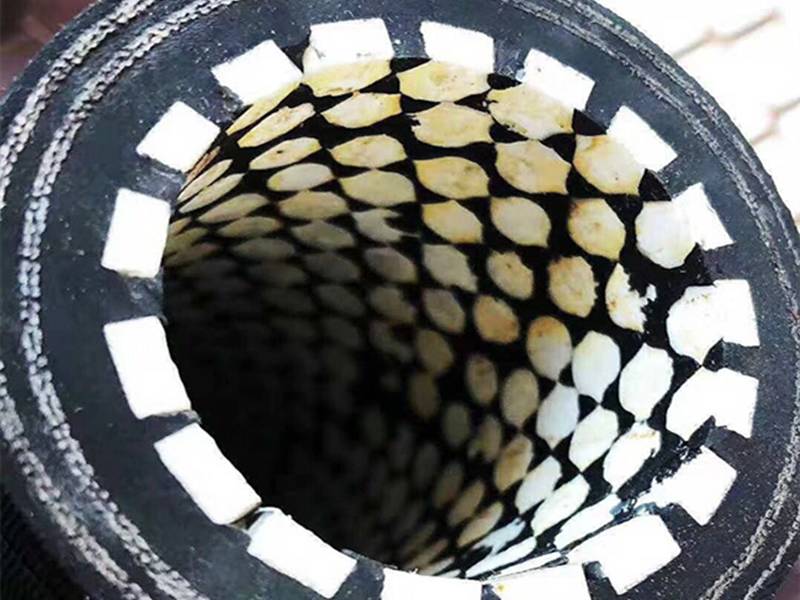

Wear-resistant ceramic rubber hose & lined ceramic rubber hose

Hose Structure:

Working principle:

High-quality wear-resistant ceramics are vulcanized inside the hose using an advanced vulcanization process. Multi-layer high-strength cords ensure that the pipeline has good compression resistance. It is not only very abrasion resistant, but also retains the soft characteristics of rubber tubes, and is generally used to isolate mechanical vibration or connect non-fixed equipment

Application:

Widely used in thermal power plants, cement plants, ore dressing plants, anti-corrosion chemicals, coal powder and slurry conveying systems, and also used in port and river dredging sand suction vessels, concrete pump trucks, etc.

Advantage:

| SIZE | OD | WP | BP | Weight | Length | |||

|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | psi | bar | psi | bar | kg/m | m |

| 25 | 1" | 47 | 150 | 10 | 450 | 30 | 1.9 | 20 |

| 32 | 1 1/4" | 55 | 150 | 10 | 450 | 30 | 2.5 | 20 |

| 38 | 1 1/2" | 62 | 150 | 10 | 450 | 30 | 3 | 20 |

| 51 | 2" | 78 | 150 | 10 | 450 | 30 | 4.4 | 20 |

| 64 | 2 1/2" | 91 | 150 | 10 | 450 | 30 | 5.3 | 20 |

| 76 | 3 | 106 | 150 | 10 | 450 | 30 | 6.7 | 20 |

| 102 | 4" | 133 | 150 | 10 | 450 | 30 | 9.2 | 12 |

| 152 | 6" | 186 | 150 | 10 | 450 | 30 | 12.9 | 12 |

| 200 | 8" | 236 | 150 | 10 | 450 | 30 | 17.6 | 12 |

| 250 | 10" | 290 | 150 | 10 | 450 | 30 | 23.3 | 12 |

| 300 | 12" | 350 | 150 | 10 | 450 | 30 | 31 | 12 |